| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Dehai Boiler |

| Model Number : | Membrane wall |

| Certification : | ISO9001 , SGS , ABS , ASME |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 800 Tons / Month |

| Delivery Time : | 50 Days |

As per client requirement panel assembly bending manhole with high quality

Water wall panel Application

Boiler water walls are membrane walls that are made of tubes welded together with or without a strip of metal in between. These walls form the enclosure of the coal combustion chamber. Water wall tubes are also referred to as the evaporator section; they contain water mostly in liquid form which gradually evaporates as it rises in the boiler.

Water wall Panel Introduction

Boiler furnace is that part of the boiler where the temperature of the system reaches the highest. The furnace produces the necessary heat required by burning the fuel oil inside its small closed chamber. Because of the fuel combustion the internal temperature goes extremely high and for this reason it is necessary that the walls of the furnace are stacked with proper high temperature withstanding material. In this article we will go through the basic furnace walls designs used in constructing a boiler.

Advantages

1. The protective effect of membrane water cooling wall on the furnace wall is the most complete, so the furnace wall only needs insulation materials, rather than refractory materials, so that the thickness and weight of the furnace wall are greatly reduced, simplify the structure of the furnace wall, reduce the total weight of the boiler.

2. Membrane water wall also has good air tightness, can adapt to the requirements of positive pressure combustion on the boiler, not easy to slag formation, less air leakage, reduce the heat loss of smoke exhaust, improve the boiler thermal efficiency.

3. it can be welded into components by the manufacturer for quick and convenient installation.

4. the use of membrane wall structure of the boiler, simple maintenance, boiler service life can be greatly improved.

| Name | Membrane water panel |

| Material | Carbon steel,Alloy,Stainless steel |

| Tube size | Φ38 - 76 mm, Customize |

| Standard | ISO , ASME |

| Model | Studded |

| Application | Istallable around the boiler combustion chamber |

| Material of base pipe | Carbon steel,Alloy steel, Aluminium or Stainless |

| Material of fins | Carbon steel,Alloy steel,Aluminium or Stainless |

| Type of base pipe | Seamlesss,Welded |

| Type of fins | welded or whole |

| OD of Base pipes | 15mm-219mm |

| WT of base pipes | 1.5-6mm |

| Width of fins | 6mm-30mm |

| WT of fins | 0.8mm-3.0mm |

| Length of blank area | according to Customer's request. |

| Length of finned tubes | ≤23m |

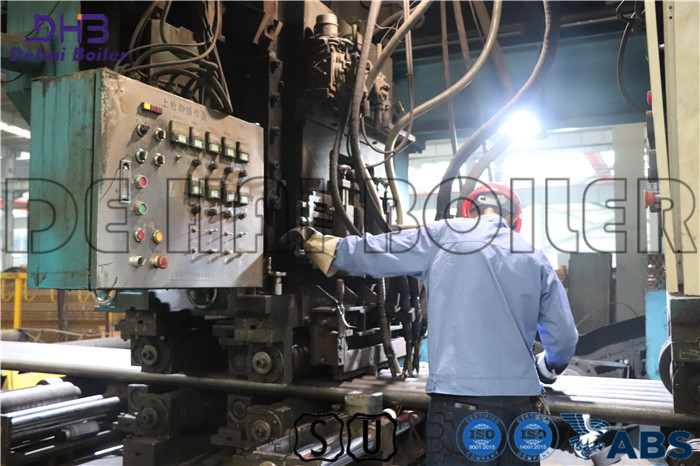

Membrane Assembly Machine(SAW)

|