| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Dehai Boiler |

| Model Number : | Economizer |

| Certification : | ISO9001 , SGS , ABS , ASME |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 800 Tons / Month |

| Delivery Time : | 45 Days |

Hot selling bare tube economizer for garbage incinerator waste to energy economiser coil

Garbage Incinerator Economiser Definition

1. Boiler Economiser ( Sometimes Called Economizer ) is the Energy improving device that helps to reduce the cost of operation by saving the fuel.

2. The economizer in Boiler tends to make the system more energy efficient.

3. In boilers, economizers are generally Heat Exchangers which are designed to exchange heat with the fluid, generally water.

Boiler Economiser and Waste Heat Recovery Concept

1. Boilers are generally designed to produce steam from water. Water is converted to steam by transferring both sensible and latent heat.

2. Sensible heat is the amount of heat required to increase the temperature of water at constant pressure without changing its liquid state, while Latent heat is the amount of heat required to change the state from Liquid to Vapor at constant temperature and pressure.

3. The exhaust from the boilers is generally in the temperature range of 200°C – 250°C, so there are a huge amount of losses from the boiler if any heat recovery devices are not installed after it.

4. If the exhaust gases which are leaving the Boiler at such high temperature is made to pass through the Economiser in order to provide the required sensible heat to the water by increasing its temperature, it will reduce the heat load on the boiler to the greater extent.

| Description | Boiler economizer |

| Material | Alloy steel, Carbon steel, SA210C ,SA213T22, etc |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton Max.:1000 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

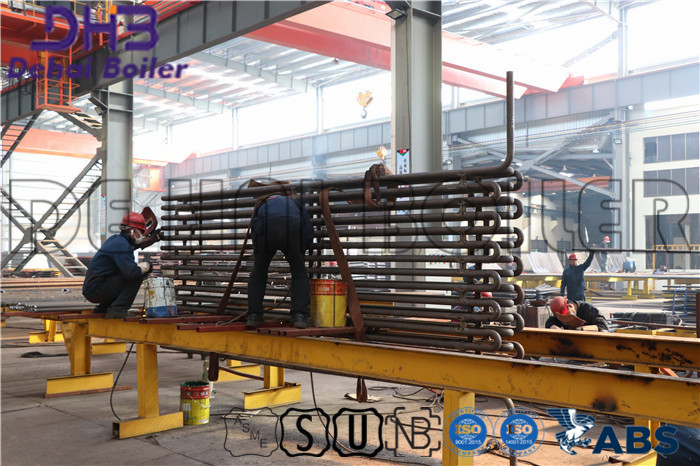

Under fabrication

|